How Plains Midstream Canada is driving towards digital transformation

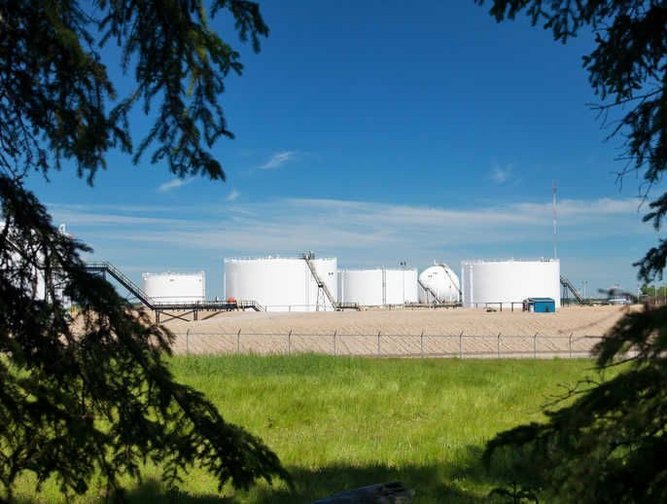

Formed in 2001 with just 130 employees, Plains Midstream Canada (PMC) has grown to over 1,400 employees and provides oil and gas transport and storage solutions across Canada and the United States. The company’s network of pipelines along with a fleet of truck trailers and railcars provide oil and gas producers with flexibility for transporting crude oil and natural gas liquids products linking petroleum producers with refiners and other customers.

The organisation is currently in the midst of a five-year digital transformation plan to drive improvements to business processes, improving the use of its existing technology or introducing new digital technologies. To design and enact this, the company brought in Chris Leonard, a Senior Business Strategist who is now their Director of Strategy and Digital Transformation. In his words, he and his team "plan the right work at the right time.”

The roadmap to digitisation is underpinned by a triad of people, process and technology improvements which means the digital strategy team can look at the business holistically instead of just focusing on a singular aspect, such as implementing new tech solutions. "Rather than having that quite narrow tactical discussion with the business around software for instance, we engage them in business terms, better understanding their needs and desired outcomes before analysing how to positively affect a change to support them. In effect we're acting as that internal technology broker, working with the business to address their problems by creating new business capabilities. Sometimes our aim is merely digitally enabling what we have, but we are absolutely planning for digital optimisation and transformation.”

"Not everything on our roadmap is about introducing technology," Leonard continues. "Often we've discovered that a review and improvement of existing business process is just as valuable."

However, he adds that they are looking at planning initiatives to add new digital assets to the business in the long term. For instance, they are looking at combining technologies such as digital twins, augmented and mixed reality, and the internet of things (IoT). “Being responsible for both OT and IT enables us to look at the whole picture, applying an IoT lens to the SCADA world for instance,” says Leonard.

Leonard has also created a strong governance structure that uses analytics to support these strategic goals, which has led to a significant rise in capital investment for Information Services (IS) led programs. “It's great having that long-term vision and roadmap, but unless you've got that governance to really help you prioritise what work you're capable of doing first, it's very difficult to see the wood for the trees,” Leonard says.

“There's always more work than there are means to complete it. We've got to ensure we're prioritising the right work at the right time, and that's inextricably linked to our digital transformation roadmap.”

He envisions that PMC’s digital transformation and partnerships with strategic vendors will result in significant cost savings. "We partnered with leading industry experts from Sapient, IBM and Microsoft to leverage global expertise and capitalise on other industry applicable use cases with a view to help accelerate the realisation of our IS strategic goals to drive enduring business value. Our Power Utilization adviser for instance, which we're co-developing with IBM Watson, will provide assessments and analysis on power consumption data at PMC facilities and pump stations which will reduce overall consumption and improve utilities management – we're really quite excited about that." Through the work they have done with Sapient to introduce a comprehensive Energy Trading and Risk Management capability, they also expect to pay significant dividends. “Working with partners such as Sapient allows us to leverage different industry expertise and apply it to our unique circumstances. It really does become a partnership where strategic vendors help us to address focused business needs.”

It is also going to be beneficial for training staff on the systems the company already uses. "Process efficiencies go hand-in-hand with introducing new digital technologies," says Leonard.

Digitising safety

Safety is a core value at PMC, and as the organisation strives for protection, security and safety of employees, the public and the environment in the communities where PMC operates, digitising safety plays a key role. Another key initial development with the IBM Watson program is the production of a Safe Work advisor. PMC is now using data analytics to assess and leverage as a tool for their safety teams to expand upon and help improve safety performance. PMC will be able to move from descriptive analysis to predictive analytics to better prevent potential incidents.

The company is also looking at future wearable technologies and how they could be used. Live information feeds could help on-site workers by helping manage potential hazards through real time information sharing without having to communicate via a radio. Leonard explains further: "We’re looking to exploit existing technologies that can read the environment an employee is in, whether they have maybe been exposed to a particular chemical, or whether an individual is showing signs or symptoms related to abnormal stress by measuring heart rate or even if that individual is still upright or on the ground, which might indicate a slip, trip or fall. The technology is creating better situational awareness without encumbering the individual to manually provide regular updates and reports."

PMC is also focused on stakeholders and is committed to maintaining strong relationships. With operations that span across Canada and the United States, the effective management, tracking and dissemination of information to their many stakeholders is vitally important. PMC is now working on a capability called "Unified Stakeholder Management" to pass crucial time-sensitive safety information onto all stakeholders.

See also:

- Talking mobile edge computing and open source software with Kontron Canada Inc.

- Food and Drug Corporation: Creating the right work culture for digital transformation

- Digital transformation at Orazul Energy: An interview with Hugo Bailon

Roadmap to the future

Looking ahead, one of the main challenges for the industry will be adapting to change. "Nobody really likes change,” Leonard says. “Advanced analytics might be able to provide greater business intelligence but existing business models and how people do business also needs to change in order to properly realise the untapped value technology can provide. Just throwing smarter technology at problems does not in itself create digital transformation."

Another challenge is the scarcity of skillsets, with a shortage of data scientists and digital security specialists in particular. However, Leonard believes this presents an opportunity for organisations to work more closely with academic institutions, helping them to tailor their programs to meet the emerging needs of businesses through the next industrial revolution.

The major disruption is yet to happen, as Leonard explains: "The big digital disruption in oil and gas will come when someone figures out how to monetise assets without actually owning them, in the same way Uber monetises the cab without owning it.”

He sees PMC as planning to take advantage of digital opportunities in the next decade. "I think our holistic digital transformation roadmap will ensure we've invested optimally in the right technology to effectively solve the right business problems and create new business capabilities. I also think we'll be sufficiently mature in our digital strategy and planning to take advantage of future opportunities created by digital disruption in the midstream segment."

On the whole it's an exciting era for Plains Midstream Canada. "It's a great time to be part of that journey, strategising and planning the right work to effectively allow an organisation to take advantage of Industrial Revolution 4.0. These opportunities don’t come around on a frequent basis."