Energy Dept. offers $50M to advance electric vehicles

Make sure to check out the latest issue of Energy Digital magazine

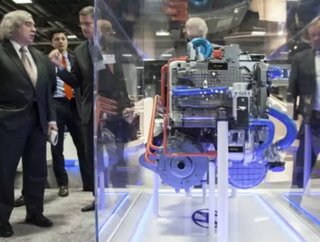

At the Washington Auto Show on Jan. 22 U.S. Energy Secretary Ernest Moniz announced nearly $50 million to accelerate research and development of new vehicle technologies that give drivers and businesses more transportation options and protect the environment in communities nationwide.

This new funding includes support for the Energy Department’s EV Everywhere Grand Challenge, a broader initiative launched in March 2012 to make plug-in electric vehicles (PEVs) more affordable and convenient to own and drive than today’s gasoline-powered vehicles within the next 10 years.

“Today, the American auto industry is on the rise, experiencing the best period of growth in more than a decade. The new research and development funding announced today will help support our domestic automakers’ continued growth and make sure that the next generation of advanced technology vehicles are built right here in America,” said Moniz.

With support from the Energy Department, U.S. automakers, universities and national laboratories have achieved significant advances in vehicle efficiency and electrification, including cutting the cost to manufacture advanced electric vehicle batteries by 50 percent over the last four years.

Building on these advancements, the funding opportunity announced this week will support a wide range of technologies that further cut fuel costs for drivers and help make vehicles more efficient and durable, including lightweight materials; cost-effective batteries and power electronics; advanced heating, ventilation and air conditioning systems; and improved fuels and lubricants.

Read more about electric vehicles:

Wireless charging the new trend for electric vehicles

'Toyota Car of the Future' debuts

New upscale electric motorcycle debuts

By bringing together America’s best engineers, scientists and businesses, the Energy Department’s EV Everywhere Grand Challenge is focused on making electric vehicles more affordable and convenient to own than today’s gasoline-powered vehicles within a decade. A new progress report released today highlights continued growth across the U.S. plug-in electric vehicle industry:

- Last year, Americans bought nearly 100,000 plug-in electric vehicles, nearly twice as many as sold during 2012. According to industry estimates, the U.S. PEV market is on track to pass the 200,000 sales milestone by spring 2014 – nearly two years before hybrid electric vehicles reached this milestone since their introduction 10 years ago.

- The Kelley Blue Book 5-Year Cost to Own Awards ranked the 2013 Chevrolet Volt as #6 on its list of vehicles that have the lowest total cost of ownership for five years after the purchase of a new car. Only compact and subcompact cars cost less over this same period.

- Through the Workplace Charging Challenge, the Energy Department is working to expand access to workplace charging stations for Americans workers across the country. In the first year of the challenge, more than 50 employers – including Facebook, Coca-Cola and Dell – have pledged to provide PEV charging access to their workforce at more than 150 worksites.

- Over the last four years, the cost to manufacture advanced electric vehicle batteries has fallen by 50 percent. At the same time, the size and weight of PEV batteries has also been reduced by over 60 percent, while improving overall vehicle performance and durability.

Photo by Sarah Gerrity, Energy Department

Photo caption: Energy Secretary Ernest Moniz looks at the fuel cell and motor used to power Hyundai’s Tucson fuel cell vehicle.