Harvard Researchers Develop First Macro-scale Thin-film Fuel Cell

Written By: John Shimkus

Thanks to advances in nanotechnology, solid-oxide fuel cells have become thinner than ever while retaining the same power output as their bulkier predecessors. This helps reduce the need for expensive component materials like platinum and yttrium. The problem, however, comes in trying to scale-up the paper-thin fuel cells, which are extremely fragile. Harvard University researchers in collaboration with Allied Minds have formed SiEnergy Systems, LLC to come up with the solution.

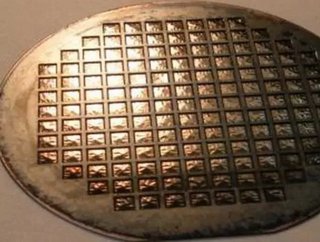

Harvard’s nanotechnology researchers have created a honeycomb-like grid to support the thin-film fuel cell. The metal wire grid helps maintain the fuel cell’s structure while also acting as a conductor. The design has proven in lab tests to provide a total output of 20 mW, the most of any thin-film solid oxide fuel cell to date. What these researchers have essentially done is proven that nano-scale thin-film fuel cells can be made scalable in size with the aid of the honeycomb grid buttress.

SEE OTHER TOP STORIES IN THE WDM CONTENT NETWORK

Collaboration and Consensus Building for Arctic Offshore Oil and Gas

Beyond Solar Panels: Six Types of Solar Power Plants

The Remote Controlled Mine: Robotic and Virtual Mining Machinery and Equipment

Check out the latest edition of Energy Digital!

Another benefit discovered in the use of the honeycomb grid is a lowered operational temperature range of 350-550 degrees Celsius versus conventional solid oxide fuel cell temperatures of 600 to 1,000 degrees Celsius.

“Although proof-of-concept nanometric thin film SOFCs operating at 350-550°C have been demonstrated before, their scalability has remained a significant challenge till now. We have successfully demonstrated scalability of nanometer thin film SOFC technology through careful optimization of metallic grid design and oxide deposition parameters,” says Dr. Masaru Tsuchiya, Principal Scientist at SiEnergy.

This breakthrough in scalable thin-film solid-oxide fuel cell technology has been published in the April 2011 edition of Nature Nanotechnology, and will be a cornerstone product in SiEnergy Systems' expanded operations, accelerating the commercialization of thin film solid-oxide fuel cells.

- IBM collaboration to boost fuel cell performance using GenAITechnology & AI

- Delayed grid connections slow energy decarbonisation effortsRenewable Energy

- Texas energy pilot to lower energy costs & reduce emissionsSustainability

- Sympower raises €22m for low carbon grid-balancing servicesUtilities