Solar Roadways: Infrastructure of the Future

Here's a glimpse into the future: high maintenance, expensive concrete roads and parking lots turned into glossy solar surfaces, fueling enough energy from the sun to power nearby communities and the electric vehicles above them.

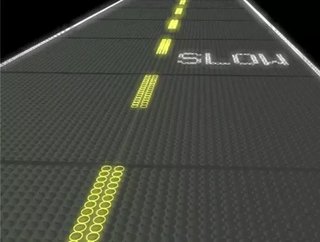

According to inventors/creators of Solar Roadways, Scott and Julie Brusaw, sections of the road could be made out of solar cells to collect energy, which would more than pay for the cost of the panel. And what if LEDs were added beneath road lines for safer night time driving and heating elements were added to prevent snow/ice accumulation is northern climates? Those are questions the Solar Roadways project sought to answer under a 2009 Federal Highway Administration contract to build the first ever prototype.

Thus far, the results have proved favorable and the company was awarded a follow-up 2-year Phase II $750,000 SBIR contract in 2011 to build a prototype parking lot.

Is the surface safe for cars to drive on? Apparently, it's safer than concrete, which collects a slick sheen of oil on its surface over time. The hardness of glass falls between steel and stainless steel. It's also easier and faster to replace than cement.

SEE OTHER TOP STORIES IN THE ENERGY DIGITAL CONTENT NETWORK

The US Army's Great Drive for Renewable Power

India set to replicate its IT sectors success in solar energy

Read more in Energy Digital's October Issue

Each road panel is made of three basic layers. The road surface layer is translucent and rough enough to provide great traction, capable of handling today's heaviest loads under the absolute worst conditions. An electronics layer would control the heating element, lighting, communications and monitoring to create an intelligent highway system. The base plate layer would take the sun collected from the electronics layer and distribute it to homes and businesses connected to the roadway.

A remarkable idea come to life, the Solar Roadway could very well become one of the greatest infrastructure innovations of the 21st century. It's time to upgrade.

- Veolia recycles landfill site into UK’s largest solar siteRenewable Energy

- Aggreko & DPWorld: Sustainable energy powering the Ryder CupSustainability

- Cubico Sustainable Investments expands renewables in UruguayRenewable Energy

- Panasonic expands successful solar battery range EverVoltTechnology & AI