Monolith receives Clean Hydrogen Production funding from MHI

Monolith Materials, a clean hydrogen and chemical production firm, has received an investment from Mitsubishi Heavy Industries America (MHI) to support its innovative, commercial-scale, emissions-free hydrogen manufacturing technology.

The announcement is the latest in a series of strategic investments made by MHI in support of achieving a decarbonised world, according to a statement. Monolith Materials is the first US manufacturer to produce a clean, industry-transforming hydrogen, known as ‘turquoise hydrogen’, on a commercial scale.

“Successfully scaling Monolith’s technology to serve a global marketplace will benefit from the kind of investment that we have from MHI,” says Rob Hanson, co-founder and CEO of Monolith Materials. “This relationship will be a model for evaluating future investment opportunities to make emissions-free hydrogen the standard around the world.”

Hydrogen, with its applications in transportation, manufacturing, energy storage and power generation, is often viewed as key to a cleaner energy future. However, the prevailing production process is not sustainable due to high CO2 emissions. The Centre for Climate and Energy Solutions states hydrogen production generates 830 million metric tons of CO2 annually, equivalent to the output of the entire country of Germany.

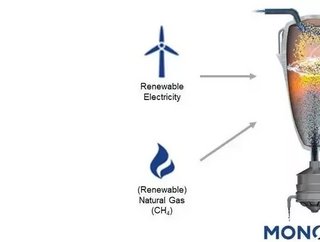

Through its proprietary breakthrough in commercial-scale methane pyrolysis, Monolith is now manufacturing emissions-free, economically sustainable hydrogen using 100% renewable energy. Monolith’s hydrogen is classified as “turquoise hydrogen,” which meets the industry standard for the cleanest hydrogen available today.

“By solving the century-old problem of scaling methane pyrolysis to a commercial level, Monolith Materials has emerged as a leader in the manufacture of emissions-free hydrogen,” says Yoshihiro Shiraiwa, president and CEO, Mitsubishi Heavy Industries America.

“While we’re evaluating a number of clean-energy development options, Monolith offers great promise. We’re excited to be the first in a new wave of strategic investors supporting the development of their technology.”

Founded in 2012, Monolith Materials has developed a process technology that converts natural gas into clean hydrogen and a solid carbon material called carbon black, a critical raw material in the automotive and industrial sectors.

The company is currently in the operating stage of Olive Creek 1 (OC1), its first commercial-scale emissions-free production facility designed to produce approximately 14,000 metric tons of carbon black annually along with clean hydrogen. In addition to producing carbon black and clean hydrogen, the company recently announced its plans to produce emissions-free ammonia at a second phase production facility known as Olive Creek 2 (OC2) in Hallam, Nebraska.

Monolith Materials’ production of hydrogen, emissions-free ammonia and carbon black are expected to reduce greenhouse gas emissions by as much as 1 million metric tons per year compared with traditional manufacturing processes.

- ABB Electrification supports GridBeyond’s AI Energy SolutionTechnology & AI

- RWE led German green hydrogen research produces hydrogenRenewable Energy

- The GHA report shows hydrogen can reduce CO2 & boost economyRenewable Energy

- Energy Impact Partners invest £30m to expand myenergiSmart Energy