The complications of 3D printing in the energy industry

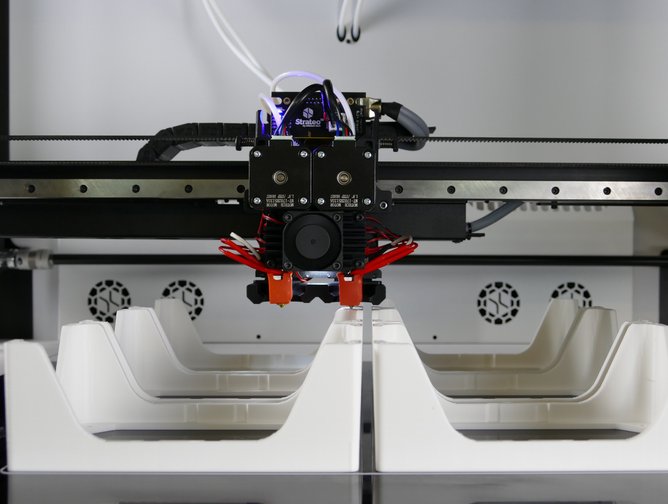

The energy industry is undergoing a period of significant transition and additive manufacturing is likely to play a substantial role in transforming the industry and its supply chain.

Due to the increased adoption of additive manufacturing processes, like 3D printing, innovators are pushing the boundaries of what can be achieved in terms of product design, energy efficiencies and roll-out speed.

As the industry looks to cut costs, create innovative solutions and improve efficiencies, we will likely see an increase in the use of additive manufacturing. This technology provides exciting opportunities, but it can also pose significant risks, particularly to patent holders who do not take the opportunities provided by additive manufacturing into account when preparing their intellectual property (IP) strategy.

So, what are those risks and why do businesses in the energy industry need to understand both IP and additive manufacturing to protect their developments?

Additive manufacturing in energy

Additive manufacturing is a broad term used to describe production methods that use digital files to control part fabrication by gradually adding material to the part, layer by layer. How material is added to the part in each layer varies from method to method, and advances in modern additive manufacturing methods demonstrates how industry-standard components can now be made out of plastics, metals, composites and even human tissue and other biological matter.

The unique advantages associated with additive manufacturing mean that use cases are already being identified within the industry. For example, studies have indicated that applications of additive technology in solar panels could reduce manufacturing costs by 50% and see a 20% increase in efficiency compared to traditional solar panels. Likewise, in the wind energy sector, 3D printing is allowing operators to produce large-scale components close to the turbine site. This not only reduces or eliminates the cost and limitations imposed by transportation, but it also allows previously unachievable turbine efficiencies to be pursued.

Key IP challenges posed by additive manufacturing in the energy industry

Increasing public focus on the energy sector, new government legislation targeting net zero, volatility caused by the pandemic and recent events in Ukraine are all contributing to accelerating change within the market. During times of uncertainty, companies will often look to their IP to protect their position within existing markets and open new opportunities. Due to the increasingly important role being played by additive manufacturing to facilitate these changes, it is critical that IP strategies and portfolios are fit for purpose in a 3D printing world.

Traditional vs additive manufacturing

Unlike additive manufacturing, where goods and products are built by adding material, most traditional manufacturing methods are subtractive processes, where material is removed from a larger block of material, or where moulds are used to form parts from a volume of molten raw material.

Established patent practices, developed with only traditional manufacturing methods in mind, are at risk of inherently linking the protection they provide to these traditional methods. This leads to a risk whereby patents drafted towards products with only traditional manufacturing in mind may be unsuitable to cover the same product made by additive manufacturing. The upshot of this is that a company’s patent, if not drafted with knowledge of additive manufacturing capabilities, may be unsuitable for protecting against a 3D-printing competitor.

In order to adequately protect against this risk, patent professionals need to have an intimate knowledge of not only the technology and the law, but also the capabilities of additive manufacturing.

Protecting your IP globally

Traditional business models often rely on manufacturing and distribution. In such cases, rather than focusing IP protection on all countries where products might be sold, companies can focus their efforts on the key manufacturing and distribution hubs in addition to key markets. This allows companies to provide a degree of control over the potential worldwide distribution of their product, without having IP rights in every potential market.

Unfortunately, where additive manufacturing is concerned, the lines between manufacturer, distributor and consumer are not always so clear. Additive manufacturing only requires a 3D printer and a digital file, both of which are readily available and fairly easy to use. Once set up and given the appropriate digital printing file, a user can make any part. This means that end users can become manufacturers, with manufacturing being distributed across the globe in line with the consumer base.

This poses a significant challenge for companies in preparing their IP strategies. If products are no longer tied to specific manufacturing or distribution hubs, how can global IP strategies best protect a company’s interests without filing in all countries of interest? Unfortunately, there is no easy answer to this, however this issue again highlights the need for IP professionals to think beyond traditional manufacturing when preparing their IP strategy – especially in a global sector, such as the energy industry.

Distribution of digital files

Perhaps the most significant IP threat facing the energy industry in light of the growth of additive manufacturing is how to control distribution of the digital files used to additively manufacture products.

Patents directed to cover physical products will typically include protection directed towards the product itself. This has, until now, been suitable to protect a company’s interest in that product – where the physical products are made centrally and then sold to an end user. However, traditionally drafted patents were not written with digital printing files in mind and there is a risk that such patents would not cover digital printing files for 3D printing the patented product. This leaves companies open to the possibility of competitors selling digital copies of their product for end users to print at home. A patent directed towards the product and drafted with only traditional manufacturing in mind may not adequately cover a competitor’s dealings in the digital file.

In order for companies to address this risk, patents and other IP rights need to be prepared with an understanding of how to cover every step in the additive manufacturing value change. Claims specifically directed towards the digital printing file are likely to become increasingly important in patent applications, in order to bridge this protection gap.

In summary, IP strategies are a significant factor in protecting and furthering a company’s interests, particularly in times of change. However, the opportunities provided by additive manufacturing may threaten traditional IP practice, and specifically concerning patent portfolios, regardless of whether the patent owner intends to use 3D printing themselves.

Byline written by Andrew Docherty and Dan Sizer from IP and trademarks firm Marks & Clerk