How Aditya Birla Textiles has established itself as an Indian textile powerhouse

From the clothes on your back to the walls around you, Aditya Birla Group is where many everyday products come to life. The Indian multinational conglomerate has a far-reaching portfolio – the group has a presence in the industries of metals and mining, cement, textiles including branded apparel, carbon black, chemicals, financial services, telecommunications and much more. Yet, regardless of the market, Aditya Birla Group has continued to leave an impression. Today, the group stands as a world leader in aluminium rolling, viscose staple fibre and carbon black production – and this pioneering approach hasn’t gone amiss within its Textiles, Acrylic Fibre or Overseas Spinning businesses either.

As a top Fortune 500 company, Aditya Birla Group also boasts the finances to back up its leading reputation, reporting a market capitalisation of about $50bn. Since its foundation over a century ago, the group has grown to become the third-largest Indian conglomerate in the private sector and, looking to the future, it has devised a new strategy to ensure it remains a global leader for years to come.

Aditya Birla Textiles – consisting of Textiles (Linen & Wool), Acrylic Fibre and Overseas Spinning businesses, has a jaw-dropping output from nine manufacturing facilities spread across five countries. Its acrylic fibre business has a capacity of about 125,000 tonnes, while its overseas spinning business has as many as 625,000 spindles and a production capacity of around 172,000 tonnes of yarn.

Reinventing the portfolio

Countering fluctuating demand and prices, Aditya Birla Textiles has taken a bold step to stay on top: it used to be a commodity player but now it has transformed its strategy to become a firm that creates unique, value-adding products. As part of this, innovation has become a top priority, helping the firm create unique products like its anti-bacterial fibre Amicor or its sustainable gel-dyed fibre Radianza. Satyaki Ghosh, CEO of Aditya Birla Group’s Textiles and Acrylic Fibre business, believes the company has devised a thorough plan for success.

“In the wool industry, our focus is not only to be a preferred supplier by ensuring quality and availability at competitive prices; we also want to proactively lead the transition of wool from a formal to casual fabric,” Ghosh says. “Therefore, we have recently invested in a facility to produce wool that is more machine washable.”

Meanwhile, in the acrylic fibre and spinning businesses, the company has increasingly focused on strategic markets and distinctive fabric applications. “Our strategy is to offer more technical and value-adding products using innovation and technology,” notes Kapil Agrawal, CEO of Overseas Spinning. “We have recently started creating more technical yarns, for instance, which are used for military, firefighting or medical purposes.”

Indeed, Aditya Birla Textiles is consistently investing in research and development to ensure it remains up to speed with the latest innovations. In doing so, Agrawal says that if a fibre can be spun, the company can spin it, using next-generation technologies like ring spun, vortex and open-end machines.

“We have also created a unique pilot plant which essentially allows us to create a product from start to finish, from spinning until garmenting,” he continues. “So, let's say my customer wants to develop a new type of trousers. I can provide a turnaround time of around seven days from when he gives me an idea. I think that's one of our most unique and differentiating factors.”

Aditya Birla Textiles doesn’t compromise on machinery either, using only top-of-the-line equipment from Europe, Japan and beyond. This helps to ensure that the best quality products are created and that they are created consistently. It also means that employees no longer need to work on repetitive tasks but can instead focus on more value-adding ones.

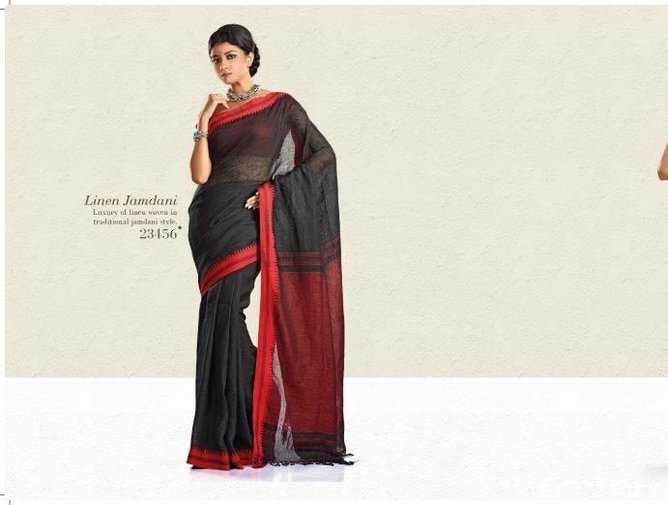

This pioneering approach has helped to position Aditya Birla Textiles’ brands among the most sought-after brands in India, with the business now standing as one of the leading producers and exporters of acrylic fibre, spun yarn, wool tops and yarns, linen yarns, fabrics and apparel. This reputation has been recognised by leading players in the apparel market like Restoration Hardware, Utenos, H&M, Speciality Fashion and Devold Norway 1853, which have all selected Aditya Birla Group as a key supplier.

“With access to world class facilities, cutting-edge technology and our state-of-the-art R&D center, we are now the fifth largest acrylic fibre producer in the world,” says Ghosh. “We’re also at the forefront of the developing domestic linen market. Our Linen Club brand enjoys leadership status in the Indian market and is a brand of choice for linen connoisseurs across the country.”

A consumer-centric commitment

Carving out a customer-driven path in the sector, Aditya Birla Group had worked hard to stay one step ahead of its customers wants and needs. In the domestic textiles market, Ghosh says that Cavallo, the company’s linen-blended apparel brand, is helping it cater to its value-seeking digital consumers. “We have launched a value-for-money, linen-rich apparel range that offers the distinct look and comfort of linen combined with the easy-care attributes of cotton,” he says. “Cavallo has been received well by the digital consumer and we are looking to up the ante here.”

Meanwhile, in the wool market, Ghosh points to the mass transition in the global fashion space from woven to knits, formal to casual wear and from dry cleaned to machine washed garments. “To tap into this segment, we have invested in the capability of producing machine washable wool and blended yarns in-house,” he notes. “Meanwhile in the acrylic fibre segment, there has been an uptick in consumer demand for customised yarns for specific applications. Therefore, we have invested in an additional production line focusing on value-added products.”

Fueling business excellence

Continuous improvement is a well-versed mantra at Aditya Birla Group, and as such the Aditya Birla Textiles business is also using innovation to revamp the way it operates. Embarking on its latest project known as ‘Mission Happiness’, Thomas Varghese, Business Head of Aditya Birla Textiles, says that the business is striving to be a top player in each of its segments. “Our entire strategy revolves around quality, achieving scale and size, achieving market share and achieving customer excellence,” he notes.

“We use a Net Promoter Score (NPS) to see the loyalty of our customer relationships. To improve this, we get regular feedback from customers; this is fed back to our teams who get into a huddle on a weekly basis to resolve any pain points almost in real time. This helps us enhance our customer satisfaction levels and improve our NPS.”

Benchmarking, lean manufacturing and six sigma projects are all commonplace at Aditya Birla Textiles. Additionally, Varghese points out that customer journey mapping is frequently used by the business. By examining consumers' touch points and resolving any hurdles, the business ensures that its top priority is always the customer. “We always like to ensure that we’re at the cutting edge by revamping and modernising our process periodically; this ensures we don’t lag behind in terms of competitiveness of technology and cost,” Varghese adds.

See also:

- Terracon: defining foundation in an emerging energy market

- How Ford Otosan’s sustainability drive is disrupting the Turkish automotive market

- By undertaking its six-year procurement strategy, Safilo has transformed its supply chain operations

A greener approach to business

Not only is Aditya Birla Textiles taking a fresh approach to its business processes, it is also thinking of new ways it can grow in a sustainable, environmentally friendly way.

United by a common sustainability vision, Aditya Birla Textiles has challenged itself to grow in a way that makes a positive difference to consumers and communities alike. By using more renewable energy, reducing its carbon emissions and cutting down its water use, for example, the firm hopes to become the benchmark for sustainable businesses.

Chief Sustainability Officer (CSO) and Vice President of Business Excellence, Jagadish Barik, says that sustainability isn’t a second-hand thought at the firm but rather a common thread that runs throughout the business. “Sustainability is a way of life for us,” he says. “It’s part of our DNA. We want to become the industry benchmark in sustainability processes and practices by 2020 through qualitative engagement with all stakeholders.” As such, the group has adopted the Higg Index, an apparel and footwear industry standard for assessing environmental and social sustainability throughout the supply chain. It has also reduced its energy consumption (increasingly opting for renewable energy sources) and has implemented a variety of far-reaching corporate social responsibility (CSR) programmes which it hopes will develop and improve the livelihood of the communities surrounding its factories.

With over 13,000 employees under its wing, Aditya Birla Textiles has been quick to understand that its people are instrumental to its day-to-day operations. As a result, the business has built a meticulous programme to develop its team. The business has increasingly used what it calls ‘two by two’ metrics, whereby employees can work in two departments, two businesses and two geographies to give them exposure to new areas of the sector. Additionally, the business is also keen to promote local talent rather than relying on expats, apparent as the some of the business units has reduced its reliance on expats by up to 30% over the last four years. This is helping to enrich local communities by providing more investment and employment opportunities. Not only the business teams predominantly local but also diverse, with women accounting for majority of its workforce in many Aditya Birla Textile units.

Investing in people, processes, technology and sustainability, Aditya Birla Textiles has established itself as a powerhouse in the textile, acrylic fibre and spinning markets. By not compromising on quality, it has ensured it will remain a leading player for years to come.